Wheel Building: Rims w/Corey Wood

Rims

The rim of a bicycle wheel is probably one of the more thought-consuming objects inside my reality. As a wheel-builder, of course, but also as a cyclist. I think that it very uniquely represents the exciting side of the physics at play throughout bicycles. The rim, by existing so close to the ground lives a life of hard-work, selfless sacrifice and, more often than perhaps is fair, sees a tragic end to its usefulness to its owner. Held at spoke's-length, with a great amount of energy it is exposed and leads the charge towards danger, adventure and the unknown. Your first line of defence. Don't worry we'll talk tires later.

Innovations in material strength and weight have helped to make the lighter rims safer and stronger Though, the guiding design philosophies still remain the same. The rim needs to be its best when it counts, and "when it counts" can be anywhere, any time.

I will say a few things mostly about road rims and wheels for now, and maybe make some sense of it....or not.

Rims: Light and Aero - A basic understanding

Making rims as light as we can while still getting what we need out of them, is a goal for rim makers and has been for a long time. With good reason, of course. Rims are rotating weight, which means they affect the way your bike accelerates, how it handles through corners, how it maintains velocity/speed via inertia. All things considered, a lighter rim can stop more quickly than a heavier one. A lighter rim requires less energy to rotate, so it climbs a hill faster and "easier". A lighter rim also usually means that there is less total material or mass in the structure, so maybe it is less rigid. Generally, this implies less durability, when apples are apples, so designing that structure to its peak is required to keep pushing the envelope on weight. Factors like accounting for tubeless tire compatibility and wider rim profiles for tire integration have come in to play too, demanding a holistic approach to this innovative thinking..

The weight or mass of the rim also affects how the rim carries momentum. Less mass results in less inertia, so it's easier to get it moving and conversely requires more energy to keep it moving once it is in motion. Your Mavic Open Pros or Stan's Alpha 340's are good examples of this, whereas your 90mm deep carbon rims provide lots of momentum with their much larger mass. But, those big deep 90mm rims also benefit from another very complimentary design detail - Aerodynamics.

When it comes to the shallower rims, as with most alloy ones, the aerodynamic attributes are boiled-down from that of their larger/deeper kin. Short of getting into yaw angles, and graphs, you can imagine how the overall rounder and slenderer shape of the rim across its length helps it slip very smoothly through the air, regardless of its incoming direction. The shallow rim is your "climbing" rim because it provides very quick acceleration, lighter overall bike weight, and energy savings in cross-winds while you might be trying to rest in a group on flat terrain.

The deeper the rim, the more beneficial forward-facing air manipulation that occurs, and also the more affected the rim is by the side-winds.(Think of swinging a sign-board through the air flat side into the wind, and then if you turn it to pass through the air length-wise, the difference in effort for each is significant.) Just because the wind is directly in your face one second, doesn't mean it won't be blowing in your right ear the next. So that big bad deep rim has its place, and for most of us it isn't the place we go everyday. The deep rim is your "flat-ground" rim because it provides strong aerodynamics for head-on wind or air and has momentum for high-speed pace riding where that headwind gets worse the faster you go. They are popular in time-trials, track racing, and triathlons for these two important qualities.

The most versatile depths of rim are 35mm-50mm because these sizes aren't too deep to climb well, and have some very noticeable aerodynamic benefits on the grinding flats sections, when a rider is pushing a big gear through the thick sea-level air. They are also now winning the big spring classics races frequently. Notorious for being very rough on the bikes, riders and equipment, it is a testament to how comfortable a modern deep aero wheel can be when designed well.

Rims: Profile, shape, feel.

The profile, or cross-section, of a rim is a defining characteristic for the above aerodynamic reasons but it also plays a role in how forgiving a wheel feels on rough terrain. I will stick to clincher rims for this, to keep the focus at the spoke nipple side of the structure. And we'll start with alloy rims.

In Eddy Merckx's day(1960's-70's), pretty much every rim was box-section or "flat-ish" on top. Through the 80's and 90's, there had been a transition into taller or deeper profiles hoping to reap the benefits of smooth-flowing air and much experimenting ensued. Prior to the introduction of carbon as a rim material, only a few companies did it right. The ride quality of those tall and sharp alloy rims was often quite harsh. The old flat-top/box-section rim was forgiving, being much more capable of momentarily deforming and returning back to shape through the wonders of elasticity because it wasn't a V shape, which physics tells us is one of the stiffest structural shapes. Until very recently, many pro tour teams were putting aside their highly-developed deep carbon wheels, and going back to the box-section tubular rims for the infamously rough spring classics races. (Some still do, but very few now). What the box-section shape doesn't provide though, is any aerodynamic benefit. The traditional rim design was also very narrow, mated to narrow tires, which made for a skinny and blade-inspired forward profile but also made for harsher ride quality than we have learned was necessary.

HED introduced their C2 rim** in 2006, with the intention of ditching the narrow rim because of its requirement of very high tire pressure to prevent the tire rolling off of the rim in high-speed tight cornering(resulting in less comfort and rigid cornering feel), for what is now becoming the standard in alloy rim design; a rim that is close to the outer width of the tire mounted on it. The change in width also brought with it a a change in the tire's shape when mounted on the wheel. What used to be a "light-bulb"-like cross section, became a smooth transition from tire sidewall surface to rim-wall surface. The tire sidewall almost stands up straight on the rim, forming a more horseshoe-like profile. This made a nice, and notable improvement in aerodynamics on even a shallow rim. With that increase in width, came a little bump in profile depth too adding further to the increased smoothness of air flow across the tire/rim interface. The tire contact patch grew, ie. more grip = good, while the rolling resistance decreased, ie. less friction = good. The tire could now be run at a lower psi and not feel slower because of it. Revolutionary. And things changed.

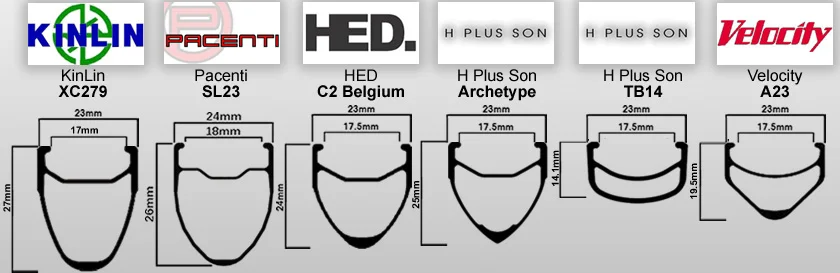

H Plus Son made their name with the Archetype, and Velocity made gains with the A23 arguably both a direct result of the C2's genius. The Archetype shape being sharper at the spoke nipple holes, a very interesting blend of U-shape and V-shape to the profile. H Plus Son's other hallmark is the TB14, is a traditional box-section rim with a beautiful laser-etched alloy valve-hole reinforcement(think Ambrosio Nemesis) save for its 23mm outer width just like it's sibling the Archetype. With an almost invisible flash-welded joint, these two rims made a place for themselves in many a wheel-builder's arsenal and credit to Velocity as the A23 became a reference point for the 23mm trend.

Continuing the progressive change in design, and setting a new benchmark for lightweight, wide-profile aero alloy rims is Kirk Pacenti at Pacenti Cycle Design. Their SL23 (my review of the Pacenti SL23 v1 rim can be found here) road rim Version 1 shook things up in the road wheel world in 2013. Lightweight for an aero shape at 440g, it boasted a 24mm outer width(18.5mm internal), and a 26mm tall profile. With solid MTB knowledge to back it up, Pacenti made it tubeless compatible too. Very nice. The Version 2 took it a step further, with a reduction in weight and most importantly an increase in the internal width of the rim from 18.5mm up to 20.3mm. I've mentioned the benefits of the added width in regards to the tire profile, including making a smoother transition to the rim surface and it is this, the internal width as opposed to external width, that most affects the tire's position and profile.

The tire's area of contact on the ground is a relatively small portion of the tire's surface area, understandably. It does a tremendous amount of work though. Changes in its shape can have interesting effects, most importantly with regards to the level of grip when cornering and how much rolling resistance is caused by the friction inherent in rubber trying to maintain a hold on the surface on which it is being used. Prior to the C2, the contact "patch" was a kind of oblong ovalized shape made by the narrow tire on a narrow rim. With the wider rim (remember that the 23mm tire is still the standard at this point, 2006-2013, so it is the rim alone making the difference) came a wider, more rounded patch that is also shorter in length. This shape inside this context means more rubber on the ground when the tire is rolled onto the outer part of the tread, in cornering, and the footprint is shorter in length resulting in less rolling resistance overall. More grip, and faster.

Currently, many riders are switching to the 25mm tire size on the road for its further increased comfort as well as that on the really wide road rims it acts very much like the 23mm did on the earlier wide models. When a 23mm tire is fully compressed(on impact, such as the far side of a pothole) while mounted on a 25-26mm rim, it doesn't provide much protection for the rim. The 25mm tire does. But, there is an aero advantage to the tire being slightly narrower than the rim(see how far we've come?), so it is a compromise.

Here comes an important distinction between running a 25mm tire on a very wide alloy rim, and running the same 25mm tire on a very wide carbon rim. As a material, carbon requires more thickness at the clincher/bead area and thus even with a wider overall rim, its inside width is still around 17mm, much narrower than the alloy.

Taking a measurement at the brake surface, where the rim's internal measurement changes the shape of the tire profile, check out how the carbon breed is a different experience than the alloy.

Alloy: Pacenti SL23 V2 clincher

Carbon: Zipp 303 Firecrest clincher

- 24.5mm external width

- 20.3mm internal width

- 26mm external width

- 17.5mm internal width

To note: An Archetype is 1.5mm narrower even than the SL23 above, and it is still wider internally than the 303.

This factor is being recognized by rim makers and as the data rolls in, efforts are being made to increase the dimension. It is really cool to see how Pacenti has had such an impact on the industry with the way they approach the problem. There is an upside to the constant changing of designs each year in a case like this, where it isn't just a new paint job on the same old frame being touted as new and improved. The changes are real, and not only can you notice and see them, you can feel them. This is a fertile time in the cycling industry and many small brands are doing really interesting, and innovative things from which we the riders reap the benefits.

That's all for now.

** The concept of "tire sensitivity" or the decrease in aerodynamics caused by the tire being wider than the rim's maximum width, was introduced by Zipp in 2001. Zipp and HED co-owned a patent beginning in the 90's that because of this kind of thinking, led to the toroidal design used on pretty much every deep carbon rim currently. HED was the first to use the "tire sensitivity" concept to improve alloy offerings it seems.

Corey Wood is the lead technician and wheel builder for Urbane Cyclist in Toronto while also a guest writer to the blog. See his expanded profile here